S-Rotary Pneumatic Vibrators-Ball

5000 INR/Set

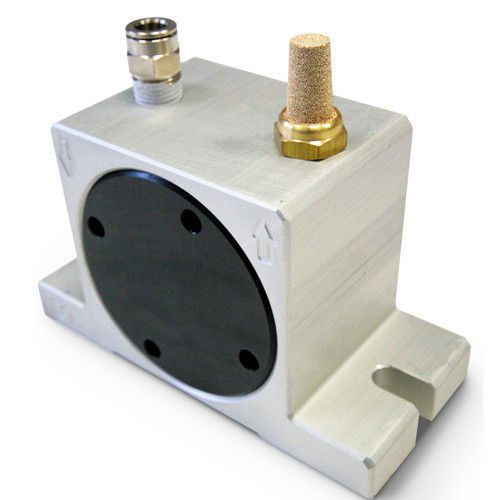

Product Details:

- Power Compressed air

- Structure Ball inside aluminum alloy cylindrical body

- Media Air

- Material Aluminum housing, steel ball

- Air Consumption 0.22 to 0.458 m/min (approx)

- Speed Up to 45,000 RPM

- Maximum Torque Varies by model, typical up to 19 Nm

- Click to View more

X

S-Rotary Pneumatic Vibrators-Ball Price And Quantity

- 1 Set

- 5000 INR/Set

- Facilitates flow in hopper, bin, silo, screen and feeder equipment

- Approx 0.9 kg to 3.5 kg (varies by model)

- up to 45,000 vibrations per minute

- -20°C to +80°C

- up to 90 dB(A)

- 2-6 Bar

- Corrosion resistant coating

- 4 bolt mounting holes

- Periodic air line lubrication recommended

- Long operating life, minimal maintenance

S-Rotary Pneumatic Vibrators-Ball Product Specifications

- Ball inside aluminum alloy cylindrical body

- 0.22 to 0.458 m/min (approx)

- Compressed air

- Varies by model, typical up to 19 Nm

- Aluminum housing, steel ball

- Up to 45,000 RPM

- Air

- Facilitates flow in hopper, bin, silo, screen and feeder equipment

- Approx 0.9 kg to 3.5 kg (varies by model)

- up to 45,000 vibrations per minute

- -20°C to +80°C

- up to 90 dB(A)

- 2-6 Bar

- Corrosion resistant coating

- 4 bolt mounting holes

- Periodic air line lubrication recommended

- Long operating life, minimal maintenance

S-Rotary Pneumatic Vibrators-Ball Trade Information

- Cash on Delivery (COD)

- 100 Set Per Month

- 1 Week

Product Description

Technical Specification

| Air Supply Quality | Class 5.4.4. |

| Application | Hopper and silo - screen - vibrating table - chute |

| ATEX | II 2D C TX, II 2G C TX |

| Max Noise Level | 90 dB(a) |

| Pneumatic Circuit | Filter + flow control valve + lubrification + 3/2 ways valve |

| Powder | Dry and granular |

| Problem Solving | Friction reduction - separation |

| Technology | Rotary vibration - high frequency |

| Working Pressure | From 2 bar to 6 bar (from 29 psi to 87 psi) |

| Working Temperature | From -20 deg C to 200 deg C (from -4 deg F to 392 deg F) |

| Material | Aluminium body and zinc plate cover |

Efficient Material Flow Solution

S-Rotary Pneumatic Vibrators-Ball are engineered to facilitate the seamless flow of bulk materials in challenging industrial environments. With a frequency range reaching up to 45,000 vibrations per minute, they help prevent clogging and ensure consistent throughput in hoppers, bins, and silos, significantly improving process efficiency and reducing downtime.

Robust Design and Versatile Applications

Featuring a durable aluminum housing and a high-grade steel ball, these vibrators are built to withstand harsh operating conditions. The corrosion-resistant coating and broad temperature range (-20C to +80C) make them reliable for varied environments. Their compact size and four-bolt mounting system allow easy integration into new or existing material handling setups.

User-Friendly Operation and Maintenance

With a simple compressed air power source and minimal maintenance needs, S-Rotary Pneumatic Vibrators-Ball offer long operational lifespans. Periodic air line lubrication maximizes efficiency, while the design supports easy installation and quick servicing. The moderate noise level makes them suitable for industrial settings where workplace comfort also matters.

FAQ's of S-Rotary Pneumatic Vibrators-Ball:

Q: How does the S-Rotary Pneumatic Vibrators-Ball improve material flow in industrial equipment?

A: By delivering rapid vibrations (up to 45,000 per minute), these vibrators prevent material bridging, rat-holing, and blockages in hoppers, bins, silos, and screens, ensuring continuous material movement and reducing manual intervention.Q: What is the recommended air pressure and lubrication process for optimal performance?

A: The recommended operating pressure ranges from 2 to 6 bar. For best results and extended service life, periodic air line lubrication should be performed to minimize internal wear and maintain consistent vibration output.Q: Where can these pneumatic vibrators be installed?

A: They are suitable for installation on a variety of material handling equipment such as hoppers, bins, silos, feeders, and screening units. The four-bolt mounting holes enable secure attachment to different structures in both new and retrofitted environments.Q: What is the typical lifespan and maintenance requirement for these vibrators?

A: These vibrators feature a long operating life due to their robust design and quality materials. Routine maintenance involves periodic air line lubrication and occasional inspection, making them low-maintenance compared to many alternatives.Q: How noisy are the S-Rotary Pneumatic Vibrators-Ball during operation?

A: They operate at a noise level of up to 90 dB(A), which is moderate for industrial vibrators of this class. Proper installation and occasional lubrication help to maintain optimal noise performance.Q: What benefits do these vibrators offer for bulk material handling efficiency?

A: They minimize downtime caused by blockages, enhance equipment throughput, and reduce the need for manual clearing of materials. The reliable aluminum-steel construction and corrosion resistance add to their durability and operational cost-effectiveness.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rotary Pneumatic Vibrators' category

|

SRI VARI ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |